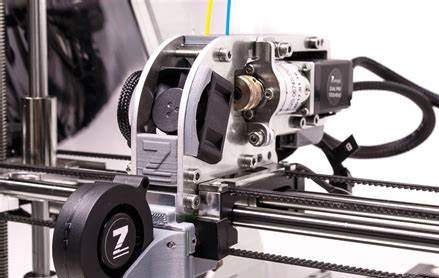

Melting Magic: Fused Deposition Modeling (FDM):

The most widely used technique, FDM, works like a hot glue gun on steroids. Plastic filament is melted and extruded, layer by layer, building objects from the ground up. Its affordability and ease of use make it ideal for hobbyists and professionals alike.

Laser Light Show: Selective Laser Sintering (SLS):

Precision takes center stage with SLS. A laser melts powdered materials like nylon or plastic, fusing them together to create intricate and complex shapes. Ideal for functional prototypes and small-batch production, SLS boasts high strength and accuracy.

Ink, Glorious Ink: Stereolithography (SLA):

Imagine sculpting with light. SLA utilizes a laser to solidify liquid resin, layer by layer, forming smooth and highly detailed objects. Often used for jewelry, medical models, and art projects, SLA delivers exceptional surface finish and intricate details.

Bound by Light, Unbound by Limits: Vat Polymerization:

Beyond SLA, vat polymerization encompasses various UV-based techniques, including Digital Light Processing (DLP). Similar in principle to SLA, DLP uses a projector to cure entire layers of resin at once, offering faster printing speeds and larger build volumes.

Metal Makeover: Selective Laser Melting (SLM):

3D printing isn’t just for plastic anymore. SLM melts metal powder with a high-powered laser, building metallic objects directly from digital files. This opens doors for aerospace, automotive, and medical applications, creating strong and lightweight metal parts.

Bioprinting: Blurring the Lines of Life:

The frontier of 3D printing pushes even further with bioprinting. Living cells are deposited and layered, potentially paving the way for tissue engineering and organ transplantation in the future. While still in its early stages, bioprinting holds immense potential for revolutionizing healthcare.

The Future is Now:

Beyond these established techniques, new materials and processes are constantly emerging. From flexible filaments to multi-material printing, the boundaries of 3D printing are continually expanding.